Infrared technology has revolutionized various industries by enabling non-contact temperature measurement and detection of thermal patterns invisible to the human eye. Mid-infrared sensors are specialized devices that detect infrared radiation in the mid-wavelength infrared band from 3 to 8 micrometers. These sensors have found widespread applications in areas like thermography, night vision, trace gas analysis and industrial process monitoring due to their unique capabilities.

What is Mid-IR radiation?

Infrared radiation is electromagnetic radiation with wavelengths longer than those of visible light. The mid-infrared region lies between the visible and thermal infrared regions in the electromagnetic spectrum. Objects at room temperature emit optimal radiation in this wavelength range depending on their temperature which can be measured using mid-IR sensors. The energy emitted is proportionate to the object's temperature according to Planck's law. Materials are also characterized by their spectral absorption features in mid-IR that allow analyzing their chemical composition.

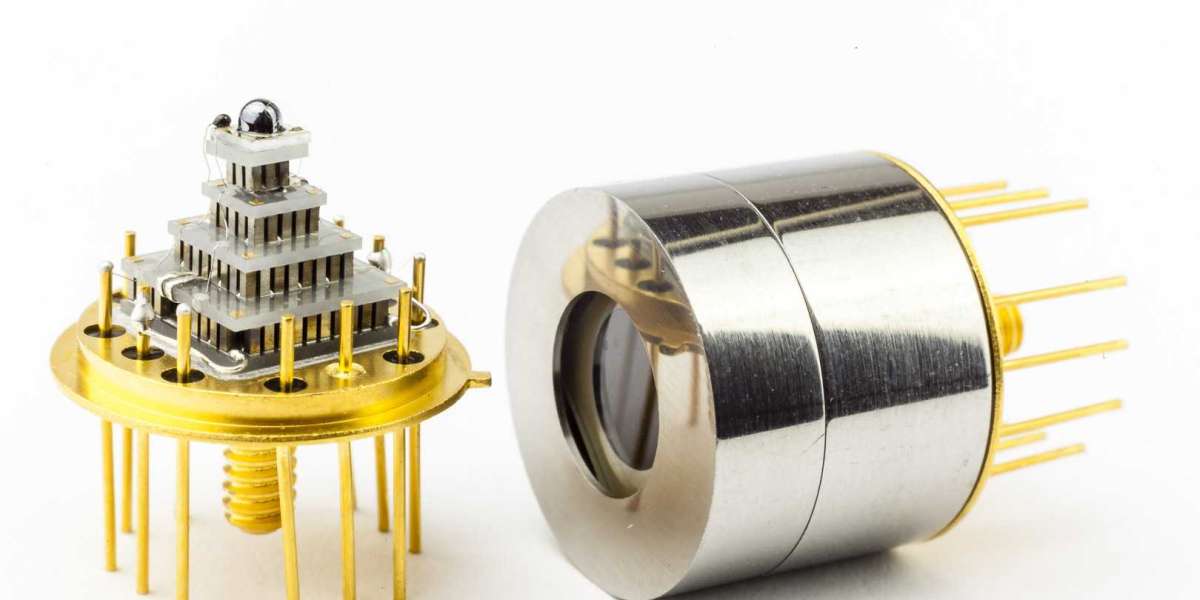

Types of Mid-IR Sensors

There are various sensor technologies that can detect mid-IR radiation including thermal detectors and photon detectors. Thermal detectors like bolometers experience a change in their electrical resistance or voltage when heated by incident infrared radiation. They have wide spectral response but relatively low sensitivity. Photon detectors like Mercury Cadmium Telluride (MCT) and Indium Gallium Arsenide (InGaAs) semiconductors generate charge carriers when photons are absorbed and are more sensitive than thermal detectors.

Mid-IR Imaging and Thermography

Thermal imaging cameras utilize Mid-IR Sensors to capture radiometric temperature maps called thermograms. They are able to detect subtle temperature differences as small as 0.1°C and find practical applications in predictive maintenance of industrial assets, construction, scientific research and medical imaging among others. Since temperature patterns create unique infrared signatures, thermal cameras are used in various security and surveillance applications to detect concealed objects even in complete darkness. They are also used for firefighting, search and rescue operations and law enforcement.

Non-Destructive Testing and Process Monitoring

Mid-IR sensors act as important tools for non-destructive testing to evaluate materials without damaging them. They help detect defects, inclusions, and delamination occurring inside solid materials and components from the analysis of their thermal behavior. In industrial plants, emission monitoring of stacks and vents is carried out using gas imaging cameras to detect leaks and abnormal gases. Mid-IR sensors continuously monitor industrial processes by remotely measuring temperatures of reactors, furnaces and ovens without direct contact. This helps optimize process parameters and ensures quality control.

Trace Gas Analysis

Due to the fact that many molecules exhibit characteristic absorption bands in the mid-IR region, trace gas analyzers use gas cells filled with the sample gas along with mid-IR light sources and detectors to identify and quantify various gases. This technique is employed for environmental monitoring of pollutants, breath analysis, leak detection, process control in petrochemical plants and quality control in the food beverage industry. Photoacoustic spectroscopy employing mid-IR lasers is a highly sensitive technique that detects parts-per-billion levels of gases.

Advancements in Mid-IR Technology

Significant progress has been made in mid-IR camera technologies to achieve higher resolution, wider temperature ranges and smaller form factors. Uncooled microbolometer arrays with resolutions exceeding 1 megapixel and temperature sensitivities of less than 50mK are now available. Quantum cascade lasers (QCLs) have expanded the accessible emission wavelengths beyond 10μm. Novel plasmonic antennas and metasurfaces are enabling wavelength-selective mid-IR detection schemes with unprecedented resolution. Perovskite nanocrystals and 2D materials like black phosphorus are emerging as new photodetector materials for the mid and far-IR regimes. These advancements are helping mid-IR sensors gain widespread use in various consumer and industrial domains.

Mid-IR sensing capabilities are revolutionizing a wide array of scientific, industrial and security applications through non-contact temperature measurement and trace gas analysis. Advancements in chip-scale uncooled detectors, laser sources and novel nanophotonic structures are expanding the utility of infrared technology across different industries like healthcare, transportation, manufacturing and environment protection. Further more advanced materials and sensing schemes promise to make mid-IR instrumentation affordable and portable opening up new possibilities in the future.

Get more insights on This Topic- Mid-IR Sensors